A torque converter is a fluid-based coupling device traditionally used in automatic transmissions to transfer engine power smoothly. In manual transmissions, it replaces the clutch, enabling seamless gear shifts and reducing driver input. This innovation combines the convenience of an automatic with the control of a manual, offering enhanced acceleration and efficiency in modern vehicles.

Overview of Torque Converters

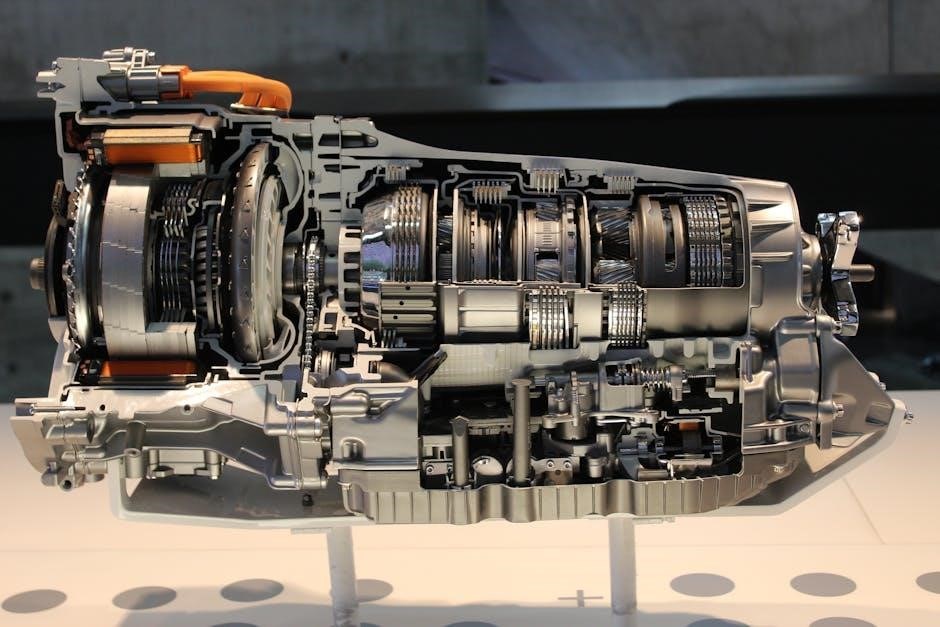

A torque converter is a fluid-based coupling device that transfers engine power to the transmission. Traditionally used in automatics, it replaces the manual clutch, enabling smooth gear transitions. By using fluid dynamics, it multiplies torque at low speeds, enhancing acceleration. Its design allows the engine to continue running while disconnecting the transmission, providing ease of operation. In manual setups, it combines the convenience of automatics with manual control, offering improved efficiency and performance. The converter’s stall speed and size are critical for optimal power delivery across various driving conditions.

Role in Manual Transmissions

In manual transmissions, the torque converter replaces the traditional clutch, allowing drivers to shift gears without pressing a clutch pedal. It enables smooth transitions between gears by momentarily decoupling the engine from the transmission. This reduces driveline shock and enhances driver comfort. The converter’s fluid coupling ensures consistent power delivery, improving acceleration and reducing wear on mechanical components. By automating the clutch function, it simplifies driving, especially in heavy traffic, while maintaining the performance characteristics of a manual gearbox. This setup bridges the gap between automatic and manual driving experiences effectively.

History and Evolution

Torque converters originated as fluid couplings in automatic transmissions, later adapted for manual use to eliminate the clutch pedal, evolving into a hybrid solution blending automatic and manual traits.

Development for Automatics

Torque converters were initially developed for automatic transmissions to replace manual clutches, providing smooth, seamless gear shifts. They utilize fluid dynamics to transfer engine power, allowing the engine to continue running while the vehicle stops. The converter’s stall speed and torque multiplication capabilities enhance low-speed performance. First introduced in the 1940s, torque converters became a cornerstone of automatic transmissions, enabling drivers to operate vehicles without manual gear shifting. Their design evolved to improve efficiency and compatibility with various engine types, becoming a standard component in modern automatic vehicles.

Adaptation for Manual Use

Torque converters have been adapted for manual transmissions to combine the smoothness of automatics with manual control. By replacing the traditional clutch, they enable seamless gear shifts without manual clutch operation. This adaptation enhances acceleration and efficiency, particularly in high-performance applications. The converter’s fluid dynamics allow for torque multiplication at low speeds, improving responsiveness. While maintaining the driver’s ability to shift gears manually, it reduces the need for constant clutch engagement, offering a blend of convenience and control in modern manual transmission systems.

Working Principles

Torque converters use fluid dynamics to smoothly transfer engine power and absorb drivetrain shock. They enable lock-up in higher gears for improved efficiency and performance.

Fluid Dynamics Explanation

Torque converters rely on fluid dynamics to transfer power between the engine and transmission. The impeller, driven by the engine, spins transmission fluid, which then engages the turbine connected to the transmission. This fluid-driven system allows smooth power transfer without direct mechanical connection. At low engine speeds, the converter multiplies torque, enhancing acceleration. As engine speed increases, the torque multiplier effect decreases, and a lock-up clutch often engages for direct power transfer, improving efficiency and reducing slippage.

Application in Manual Setups

Torque converters are increasingly integrated into manual transmissions to enhance performance and ease of use. By replacing the traditional clutch, they enable smooth, driver-free gear engagement, reducing wear on components. This setup is particularly beneficial in high-performance vehicles, where rapid power delivery is crucial. The converter allows for seamless acceleration and improved torque management, making it ideal for both racing and everyday driving applications. This hybrid system combines the best of automatic and manual transmissions, offering a balanced experience.

Stall Speed Determination

Stall speed is the maximum RPM a torque converter can reach without transmitting power, crucial for optimizing performance in manual transmissions. Proper calculation ensures efficient power delivery.

Methods for Calculation

Calculating stall speed involves measuring engine RPM, torque, and transmission specifications. Using formulas that account for fluid dynamics and gear ratios, technicians determine optimal stall speeds. Specialized tools and software aid in precise measurements, ensuring the torque converter aligns with the engine’s performance characteristics for enhanced efficiency and power delivery in manual setups.

Tools and Techniques

Stall speed calculation requires specialized tools like tachometers and dynamometers to measure engine RPM and torque output. Techniques involve analyzing gear ratios and fluid dynamics within the torque converter. Advanced software models engine performance, ensuring accurate stall speed matching for manual transmissions. Proper alignment and installation tools are also essential to prevent damage and optimize efficiency during setup.

Installation and Alignment

Proper installation involves aligning the torque converter with the transmission and engine, ensuring it seats correctly. Use specialized tools to avoid damage and ensure precise alignment.

Step-by-Step Installation Guide

Inspect Components: Ensure all parts are clean and undamaged. Check torque converter for proper rotational freedom.

Mount Engine: Secure engine and transmission assembly. Align torque converter with input shaft.

Install Converter: Gently slide torque converter onto input shaft, ensuring it seats fully without force.

Align Splines: Verify splines align correctly between converter and transmission.

Secure Housing: Attach torque converter housing to transmission using provided bolts.

Tighten Bolts: Tighten bolts in a star pattern to avoid warping.

Reconnect Components: Reattach driveshaft and other connected parts.

Test System: Start engine and check for leaks or unusual noises.

Alignment Best Practices

Proper alignment is crucial for torque converter installation. Ensure the center bush is installed to prevent damage.

Use alignment tools like pilot bearings or bushings to guide the converter onto the input shaft.

Check the converter’s orientation and ensure it is flush with the transmission face.

Align the driveshaft with the transmission output shaft to avoid vibration.

Never force parts into place, as this can cause irreversible damage.

If unsure, consult a professional to ensure accurate alignment and prevent future issues.

Manual vs. Automatic Transmissions

Manual transmissions rely on driver-operated clutches for gear shifts, offering control and fuel efficiency. Automatics use torque converters for smooth, hands-free shifting, prioritizing convenience over driver input.

Clutch vs. Torque Converter Roles

The clutch in manual transmissions disconnects the engine from the gearbox, allowing gear shifts without torque interruption. In contrast, a torque converter uses fluid dynamics to multiply torque and enable smooth power transfer in automatics. While the clutch requires driver input, the torque converter operates automatically, providing a seamless driving experience. This fundamental difference impacts both driver control and vehicle performance, with clutches offering precision and torque converters enhancing convenience.

Pros and Cons Comparison

Using a torque converter in a manual transmission offers smooth power delivery and reduced clutch wear, ideal for heavy traffic. However, it adds weight and complexity, potentially lowering fuel efficiency in city driving. While it enhances low-speed maneuverability, it may reduce driver control and connection to the vehicle, a trade-off for convenience. This setup balances ease of use with slight performance compromises, making it suitable for specific driving conditions rather than all scenarios.

Impact on Acceleration and Efficiency

Torque converters in manual transmissions can improve acceleration by 3-5 seconds in 0-60 times, enhancing low-speed torque multiplication. However, this may slightly reduce fuel efficiency in city driving.

Performance Effects

The integration of torque converters in manual transmissions significantly enhances acceleration, particularly in low-speed scenarios, by multiplying torque and providing smoother power delivery. This setup allows drivers to achieve quicker 0-60 times, improving overall vehicle responsiveness. Additionally, the lock-up feature in higher gears minimizes power loss, ensuring efficient energy transfer. However, the added weight and potential horsepower loss at higher RPMs can slightly offset these benefits. Despite this, the improved low-end torque and seamless shifting make torque converters a viable option for drivers seeking a balance between performance and convenience.

Fuel Efficiency Considerations

Torque converters in manual transmissions can impact fuel efficiency in mixed driving conditions. While they enhance low-speed torque delivery, the increased weight and potential slippage during gear changes may reduce mileage. However, lock-up functionality in higher gears helps minimize energy loss, contributing to better highway efficiency. Proper calibration and maintenance are crucial to optimize fuel performance. Balancing these factors ensures that torque converters can offer improved efficiency without compromising the benefits of manual transmission control.

Types of Torque Converters

Torque converters vary by size, stall speed, and application, including single-stage, multi-stage, and locking designs. They also come in high-performance and heavy-duty models for specific needs.

By Size and Stall Speed

Torque converters are categorized by size and stall speed, with smaller units suited for low-torque applications and larger ones for high-performance engines. Stall speed determines when the converter engages, balancing engine horsepower and vehicle demand. Single-stage converters are common in passenger vehicles, while multi-stage designs optimize performance across varying speeds. Locking torque converters enhance efficiency in racing applications by eliminating slip. Size and stall speed are critical for matching the converter to engine specifications, ensuring optimal power delivery and drivetrain compatibility.

Application-Specific Types

Torque converters are tailored for specific applications to maximize efficiency and performance. Racing converters prioritize high stall speeds and rapid engagement for explosive acceleration, while heavy-duty types are built for towing and hauling. Street converters balance daily driving comfort with moderate performance, offering smooth engagement. Lock-up converters minimize slip for enhanced fuel efficiency, often used in hybrid and eco-focused vehicles. Each type is engineered to meet distinct demands, ensuring optimal adaptability across various driving scenarios and vehicle requirements.

Maintenance and Repair

Regular fluid checks and inspections prevent wear. Replace worn components promptly to avoid damage. Proper alignment during installation ensures smooth operation and prolongs lifespan of the torque converter.

Regular Maintenance Tips

Regular fluid level checks ensure optimal performance. Replace transmission fluid as recommended to prevent degradation. Inspect for leaks and wear on the torque converter and surrounding components. Clean or replace the filter to maintain fluid flow. Check alignment during installation to prevent imbalance and vibration. Monitor operating temperatures to avoid overheating, which can damage the converter. Address any unusual noises or vibrations promptly to prevent further issues. Routine inspections can extend the lifespan and efficiency of the torque converter in manual transmissions.

Repair and Troubleshooting

Identify common issues like slipping, vibration, or stalls. Inspect for worn or damaged components such as seals or bearings. Check fluid levels and condition, replacing if degraded. Address leaks promptly to prevent further damage. Verify proper installation, as misalignment can cause failure. Use diagnostic tools to measure stall speed and ensure it matches engine specifications. Replace faulty solenoids or sensors controlling converter lock-up. In severe cases, rebuild or replace the torque converter to restore smooth operation and prevent transmission damage.

Case Studies and Applications

Real-world applications show torque converters enhancing manual transmissions in high-performance cars, such as the Honda Prelude SH, improving acceleration and drivability. Racing setups often utilize modified converters for optimized power delivery.

Racing and High-Performance

In high-performance racing, torque converters are adapted for manual transmissions to enhance acceleration and control. By eliminating the clutch pedal, drivers can focus on gear shifts, improving lap times. Modified converters with optimized stall speeds are used in drag racing for quicker launches. However, the added weight and potential horsepower loss remain trade-offs. The Honda Prelude SH model exemplifies this setup, combining the precision of a manual with the smoothness of a converter, proving effective in competitive environments while maintaining driver engagement.

Specific Car Models

Certain car models have successfully integrated torque converters with manual transmissions, such as the Honda Prelude SH. This setup offers a blend of automatic convenience and manual control. The 1.5-liter turbocharged Honda Si also features a precise six-speed manual, achieving up to 37 mpg highway. These models demonstrate how torque converters can be adapted to enhance performance without sacrificing efficiency, appealing to drivers seeking a balance between power and fuel economy in both everyday driving and high-performance scenarios.

Myths and Misconceptions

A common myth is that torque converters in manual transmissions reduce driver control. However, they actually enhance smooth shifting while maintaining manual gear engagement, dispelling concerns about loss of precision and responsiveness.

Debunking Common Beliefs

One widespread misconception is that torque converters in manual transmissions compromise driver control. This is false, as they maintain precise gear engagement while enhancing smoothness. Another myth is that they reduce fuel efficiency, but modern designs optimize performance without significant losses. Additionally, the belief that torque converters are only for automatics is incorrect, as they can seamlessly integrate with manual systems, offering the best of both worlds: ease and control.

Clarifying Performance Impact

Torque converters in manual transmissions enhance low-end torque delivery, improving acceleration without sacrificing control. They minimize power loss during gear shifts, offering smoother transitions. While they slightly reduce top-end horsepower due to fluid coupling inefficiency, the trade-off is minimal. Fuel efficiency remains comparable to traditional manuals, with gains in drivability. Contrary to myths, they don’t diminish the manual driving experience but rather complement it, providing a blend of power and precision.

Modifications and Upgrades

Aftermarket torque converters and custom tuning options enhance performance, optimizing acceleration and efficiency for manual transmissions, while addressing specific drivetrain needs and improving overall vehicle responsiveness.

Aftermarket Solutions

The market offers various aftermarket torque converters designed for manual transmissions, providing improved torque multiplication and stall speeds. These solutions cater to high-performance needs, enhancing acceleration and responsiveness. Custom tunings allow drivers to optimize their torque converters for specific applications, ensuring better power delivery and fuel efficiency. Upgraded components, such as high-capacity stators and reinforced housings, are also available, enabling increased durability and performance under demanding conditions. These modifications make manual transmissions more versatile and capable for both racing and everyday driving scenarios.

Custom Tuning Options

Custom tuning options for torque converters in manual transmissions allow precise calibration to match engine specifications and driving preferences. By adjusting the stall speed and torque multiplication, drivers can optimize performance for specific conditions, such as racing or towing. Advanced software and mechanical modifications enable tailored power delivery, enhancing both acceleration and efficiency. These tunings can be fine-tuned to complement engine upgrades, ensuring maximum utilization of available power and torque. This level of customization provides a competitive edge in performance while maintaining drivability in everyday scenarios.

Legal and Safety Considerations

Installing a torque converter in a manual transmission requires adherence to legal standards and safety protocols to ensure compliance and avoid mechanical failure, emphasizing proper installation techniques and professional oversight.

Regulatory Compliance

Regulatory compliance is crucial when integrating a torque converter into a manual transmission. Local and federal regulations often dictate specific standards for emissions, safety, and performance. Modifications must meet these requirements to avoid legal penalties. Additionally, certifications from recognized automotive authorities may be necessary, particularly for aftermarket installations. Compliance ensures the system operates safely and efficiently, minimizing environmental impact and maintaining roadworthiness. Always consult local regulations and seek professional oversight to guarantee adherence to legal and safety standards.

Safety Precautions

When working with torque converters in manual transmissions, safety precautions are paramount. Always disconnect the battery and ensure the vehicle is securely supported on jack stands. Wear protective gear, including gloves and safety glasses, to prevent injury from moving parts. Properly vent the system to avoid hydraulic fluid exposure, which can be hazardous. Never test drive the vehicle until all connections are verified and the system is functioning correctly. Adhering to these precautions minimizes risks and ensures a safe working environment for both the technician and the vehicle occupants.

Future Trends

Future trends in torque converter technology focus on enhancing efficiency and integration with hybrid systems. Innovations in fluid dynamics and material science aim to optimize performance and reduce weight, ensuring smoother power delivery while maintaining fuel efficiency in evolving manual transmission applications.

Advancements in Technology

Recent advancements in torque converter technology for manual transmissions focus on improving efficiency and responsiveness. Hydraulic systems now incorporate advanced solenoids and sensors, enabling precise control over fluid flow and torque multiplication. Lightweight materials and optimized designs reduce inertia, allowing quicker engagement and disengagement. Integration with electronic control units ensures seamless communication with other vehicle systems, enhancing overall performance. These innovations aim to bridge the gap between manual and automatic transmissions, offering drivers the best of both worlds in terms of control and convenience, while maintaining optimal power delivery and fuel efficiency.

Integration with Other Systems

Modern torque converters in manual transmissions are increasingly integrated with advanced vehicle systems, such as traction control and adaptive cruise control. This integration enhances stability and responsiveness by synchronizing torque delivery with real-time data from sensors. Additionally, torque converters now work in tandem with hybrid powertrains, optimizing energy recovery and reducing emissions. Integration with driver-assistance systems also improves safety by preventing wheel slip during acceleration. These advancements ensure that torque converters not only improve transmission performance but also contribute to a more connected and efficient driving experience.

Torque converters in manual transmissions offer a unique blend of automatic and manual benefits, providing smooth power transfer and improved acceleration while reducing clutch operation needs.

Final Thoughts

Torque converters in manual transmissions represent a fascinating blend of traditional and modern drivetrain technology. By eliminating the need for manual clutch operation, they offer unparalleled convenience while retaining the performance characteristics of a manual setup. This hybrid approach not only enhances driver comfort but also improves low-speed maneuverability and acceleration. However, the added complexity and potential cost may not appeal to purists seeking a traditional manual experience. Despite these trade-offs, the integration of torque converters in manual transmissions underscores the automotive industry’s continuous pursuit of innovation and efficiency.

Future Outlook

The integration of torque converters in manual transmissions is expected to evolve significantly, blending traditional mechanics with advanced technology. Future developments may focus on optimizing fluid dynamics for higher efficiency and torque multiplication. Hybrid systems combining torque converters with dual-clutch mechanisms could emerge, offering enhanced performance and seamless shifting. Additionally, advancements in materials science may lead to lighter and more durable components, further improving reliability. As automotive technology progresses, torque converters in manual transmissions could become a cornerstone of next-generation drivetrains, balancing performance, efficiency, and driver convenience.